- Toolsidee.co.uk >

- < Metal lathes >

- HBM 360 x 1000 DRO Industrial Metal Lathe Complete with Large Bore

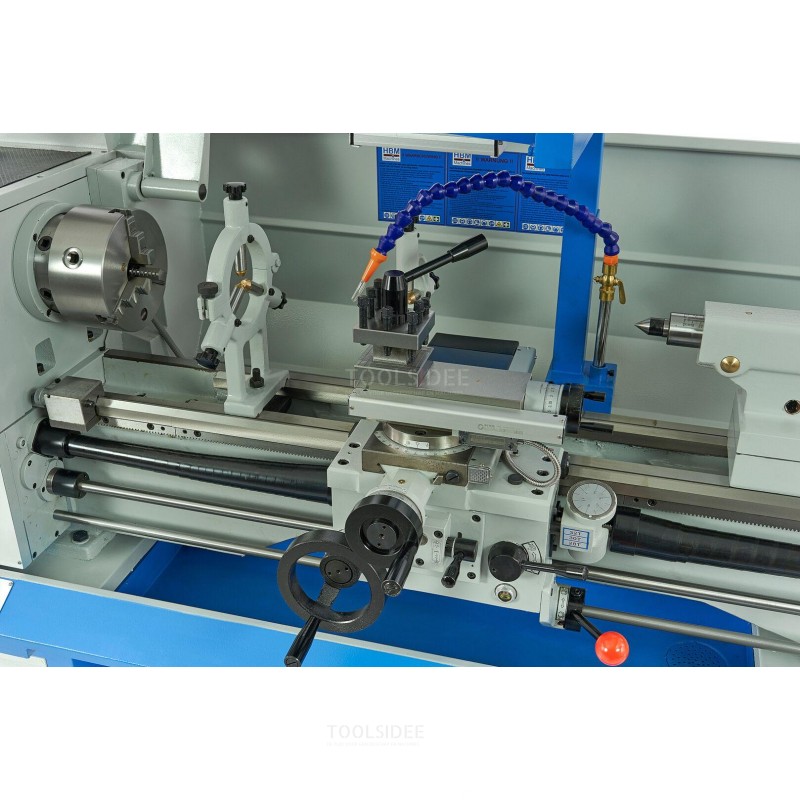

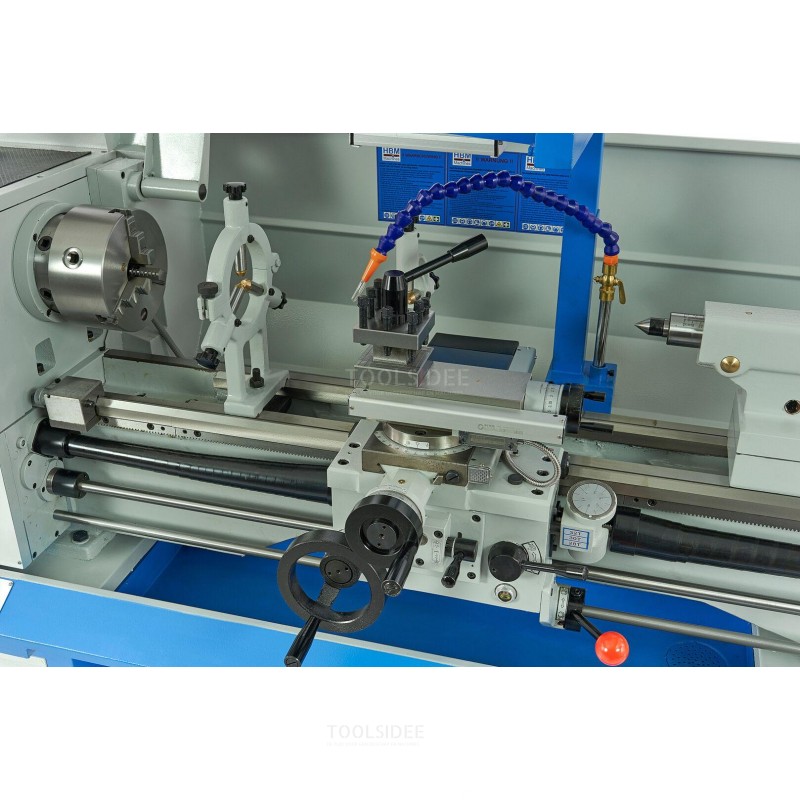

HBM 360 x 1000 DRO Industrial Metal Lathe Complete with Large Bore

Out of Stock

- Description

Technical data of the HBM 360 x 1000 DRO Industrial Metal Lathe Complete with Large Bore. Turning diameter above the bed 360 mm. Center height 180 mm. Turning diameter in bag of the bed 502 mm. Turning diameter over cross support 220 mm. Distance between centers 1000 mm. Bed width 185 mm. Displacement of the cross support mm. Displacement of the cone support mm. Passage of the main shaft 52 mm. Chuck chuck DIN 55029 - Camlock D1-5. Speed range 70 to 2000 RPM. Thread range imperial (withworth) 4 - 56 TPI. Thread cutting range metric 0.4 - 7 mm. Longitudinal feed range 0.052 - 1.392 mm / O min. Cross feed range 0.01 - 0.380 mm / O min. Spindle stroke 100 mm. Pinole diameter 42 mm. Recording of the pinole MC 3. Motor power 400 Volt 1500 / 2200 Watt. Motor power 230 Volt 1500 Watt. Voltage 400 Volts. Weight 575 kg. Machine dimensions 182.5 x 75 x 160 cm. Packaging dimensions 192 x 76 x 156 cm. This metal lathe is supplied as standard including. 3 Chuck 200 mm. 4 Chuck 200 mm. Fixed goggles "“ diameter max. 70 mm. Passing glasses "“ diameter diam. max. 60mm. Clamping plate 280 mm. 4 - way tool holder. LED-lighting. Foot pedal with brake function according to CE. Motor with magnetic brake according to CE standard. Base with removable drip tray / chip tray Hardened and ground bed rails. Longitudinal and transverse feeding. Complete cooling device. Protected against zero voltage. SINO 3 axis digital readout system completely mounted Chuck and support protection. threading clock. reducing sleeve. Set of change wheels. 2 Centering points. Micrometer longitudinal stop. Associated tools. Other specifications. In order to minimize the influence of vibrations, the solid prism bed is also provided with ridges. Standard with 52 mm bore for machining large diameters. Optimally suited for processing steel, NE materials and plastics. Removable bridge for processing large diameter workpieces. Space-saving installation option due to the chip tray that can be pulled out to the front. The speed and feed setting is easy to set up, smooth and precisely switchable. Electromechanical foot brake to reduce adjustment times. Modern main spindle bearing with precision angular contact ball bearings. Cast steel prism bed, induction hardened and precision ground. Guaranteed accuracy in the spindle. (0.009 mm) Main spindle hardened and ground, running in oil bath. Loose head, spindle stick and all guides are adjustable. Tailstock can be shifted ± 5 mm for taper turning.

Article number: 7652-E

Write a review

You help others with their choice by sharing your experience.

Fast shipping throughout Europe!

Fast shipping throughout Europe!  Reflection period 14 days

Reflection period 14 days  Delivery times 1 - 3 working days

Delivery times 1 - 3 working days

4,4 based on 47 reviews

Our company

Contact details

De Goudse Gereedschaphandel B.V.

Ambachtweg 19

2841 MA Moordrecht, The Netherlands

Company registration number 86249959

phone number: +31 (0)182787368

E-mail: [email protected]

NL

NL DE

DE FR

FR £ UK

£ UK IT

IT NO

NO ES

ES SE

SE DA

DA FI

FI